- Medical automation equipment

- Automatic equipment for blood glucose test paper production

- Colloidal gold test paper production automation equipment

- Automatic filling equipment for biological reagent production

- Micro quantitative spray point equipment and automation platform

- Medical devices & consumables production and assembly equipment

- Automatic equipment for drug sorting and packaging

- Educational training equipment

- CCD visual inspection equipment

- Intelligent production line equipment

Product Details

1. Application:

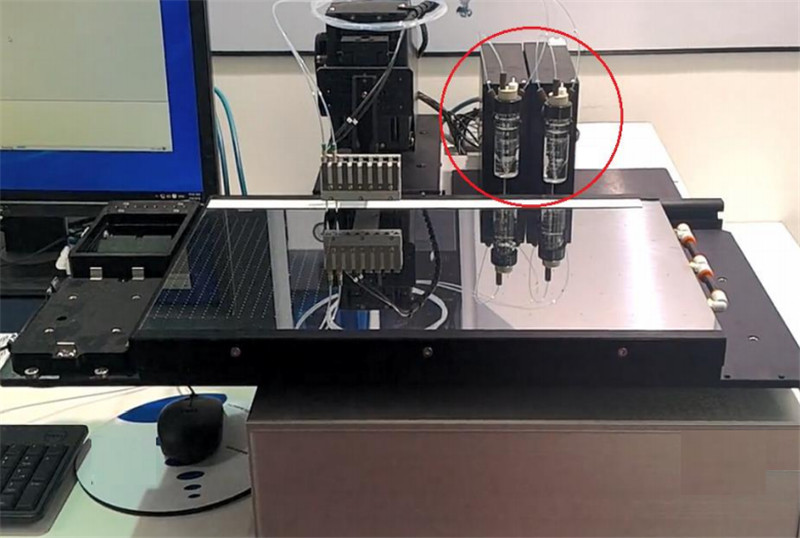

Used for the preparation of rapid test strips. This 3D dispensing/dotting system for test strips employs internationally advanced Controlled Solenoid Valve combined with a high-precision stepper pump system, enabling movement along the X, Y, and Z axes. The dispensed solution can form dots or lines, offering precise quantification and excellent reproducibility. The dispensing speed is freely adjustable and configurable, making it suitable for the micro-quantitative dispensing of biological reagents, antibodies, etc., and ideal for the research and production of rapid detection products such as test strips and biosensors.

2. Technical Specifications:

(1) The platform can be configured with various dispensing heads as needed, suitable for the dispersed quantitative dispensing of gold-labeled reagents, blocking buffers, pretreatment solutions, etc. The dispensing heads are supplied with solution by high-precision stepper pumps.

(2) X-axis travel speed: 50-250 mm/s; Y-axis travel speed: 100 mm/s; Z-axis travel speed: 100 mm/s; X, Y, Z-axis positioning accuracy: ±0.2 mm; Line dispensing head positioning accuracy: ±0.2 mm.

(3) Minimum spacing between dispensing heads: 2 mm; Spacing adjustment method: Lead screw stepless adjustment; Solution volume for line dispensing stepper pump: 500 μl; Solution volume for gold conjugate dispensing stepper pump: 1000/2500 μl; Solution dispensing concentration: 0.2-10 μl/cm; Minimum aspiration/dispense volume: 1 μl; Solution residual volume: Approximately zero.

Air pressure requirement: 40-60 PSI (Requires user to provide one standard nitrogen gas bottle)

3. Equipment Parameters:

Platform size: 450mm × 70mm (Customizable)

Platform movement speed: 0-330mm/sec

X, Y, Z axis movement error: < 50μm

Positioning accuracy: ±10μm in 1 axis ±25μm in 2 axes

Dispensing Method: PDB1000: Non-contact dispensing PDA1000: Non-contact dispensing

Line Width: PDB1000: 0.50mm/line (Dispensing: 0.20mm/drop) PDA1000: 0.5-5mm

Minimum Dispensing Volume: PDB1000: 10 nl/drop PDA1000: 1 μl/cm

Line Dispensing Precision: PDB1000: ±1 PDA1000: ±2

Air pressure: 40-60 PSI (Requires user to provide one standard nitrogen gas bottle)